Boosting supply chain resilience

Acronym

Flex4Res

Started

1st January 2023

Ends

31st December 2025

Budget

€10 000 000

Strategic Objective

Foster sovereignity and competitiveness

Sector

Industrial Manufacturing

Activity Leader

Emmanouil Bakopoulos

Project coordinator

Laboratory for Manufacturing Systems & Automation (LMS), Greece

About the project

The European research project Flex4Res concentrates on making supply chains more resilient. Flex4Res stands for data spaces for FLEXible production lines and supply chains FOR RESilient manufacturing,

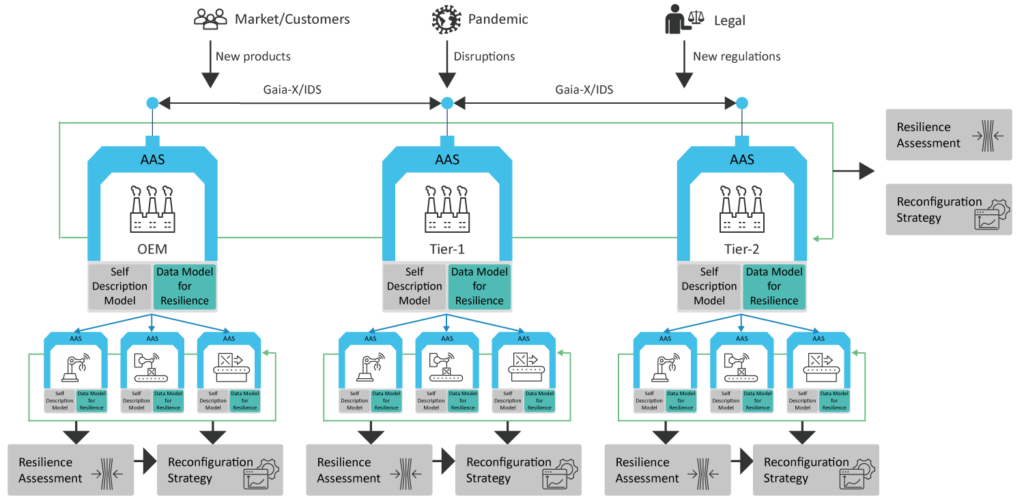

To achieve this, the project partners are developing an open platform for secure and sovereign data exchange along the supply chain to support the reconfiguration of production networks. They are also developing two toolboxes: one for resilience assessment and one for reconfiguration planning. These toolboxes allow different players in the supply chain to effectively and rapidly adjust to various disruptions, both in their supply chains and in their production processes.

With 17 partners from six EU countries (Austria, Belgium, Greece, Luxemburg, Germany and Spain), a multi-perspective approach to the challenges companies across Europe face is ensured.

Challenges

Today’s supply chains are complex and global. This makes them vulnerable to disruptions from pandemics, natural disasters, cybersecurity attacks or economic crises. However, companies need to consistently deliver high-quality products while also minimising non-value-adding activities.

“With Flex4Res, we have the opportunity to connect stakeholders across the entire supply chain and enable them to manage different types of disturbances through a trusted and secure method of data sharing. Thanks to interoperability, it is also without barriers.”

Kosmas Alexopoulos

Senior Research Engineer

Laboratory for Manufacturing Systems & Automation (LMS)

Solutions

Based on the latest Gaia-X framework, International Data Space (IDS) Reference Architecture Model and Asset Administration Shell (AAS) technology, Flex4Res implements an industrial data space for sharing digital twin models of production facilities that are stored in AAS middleware. Knowledge-based and easy-to-integrate smart tools from the toolboxes complete the concept and support users with recommendations for corrective actions so that they can make smarter decisions regarding their systems from a resilience perspective.

Societal impact

The project supports a more resilient, sustainable and competitive manufacturing sector. This benefits society by supporting economic stability through competitive manufacturing and secure employment as well as ensuring the continuous supply of goods.

Expected results

Flex4Res focuses on strengthening the flexibility and therefore the resilience of the European manufacturing industry by enabling manufacturers to reconfigure supply chains and production lines fast and efficiently.

With four industry-related use cases, the project addresses different types of manufacturing systems and focuses on various hierarchical layers: macro, meso and micro level.

Participants

LMS

TU Darmstadt

CONTACT Software

EIT Manufacturing Central

IDEKO

Soraluce

TU Darmstadt

TU Wien

voestalpine

Sidenor

GOIMEK

A1 Digital

BEIA

Hans Berg

SAVVY

Universitat Siegen

Netcompany-Intrasoft